Material Flow Optimization For Compressing Time to Launch and Reducing Indirect Labor Costs

As a manufacturer you can invest millions of dollars in thousands of industrial engineering man-hours, in an effort to squeeze as much productivity out of your direct labor as possible – machines on the line, tooling and fixtures, workers at their stations and production processes. But what about indirect labor? Surprisingly, very little gets invested towards indirect labor evaluations. The signs of trouble are often difficult to see – operational costs might be running high for unexplained reasons or there might be abnormal levels of non-value added work being performed. Manufacturers like yourself can have difficulty quantifying and analyzing in-direct labor, which causes you to turn back to what you know best – direct labor issues. In the meantime the quest to achieve lean and efficient operations remains just out of reach because only half of the factory operations are being evaluated.

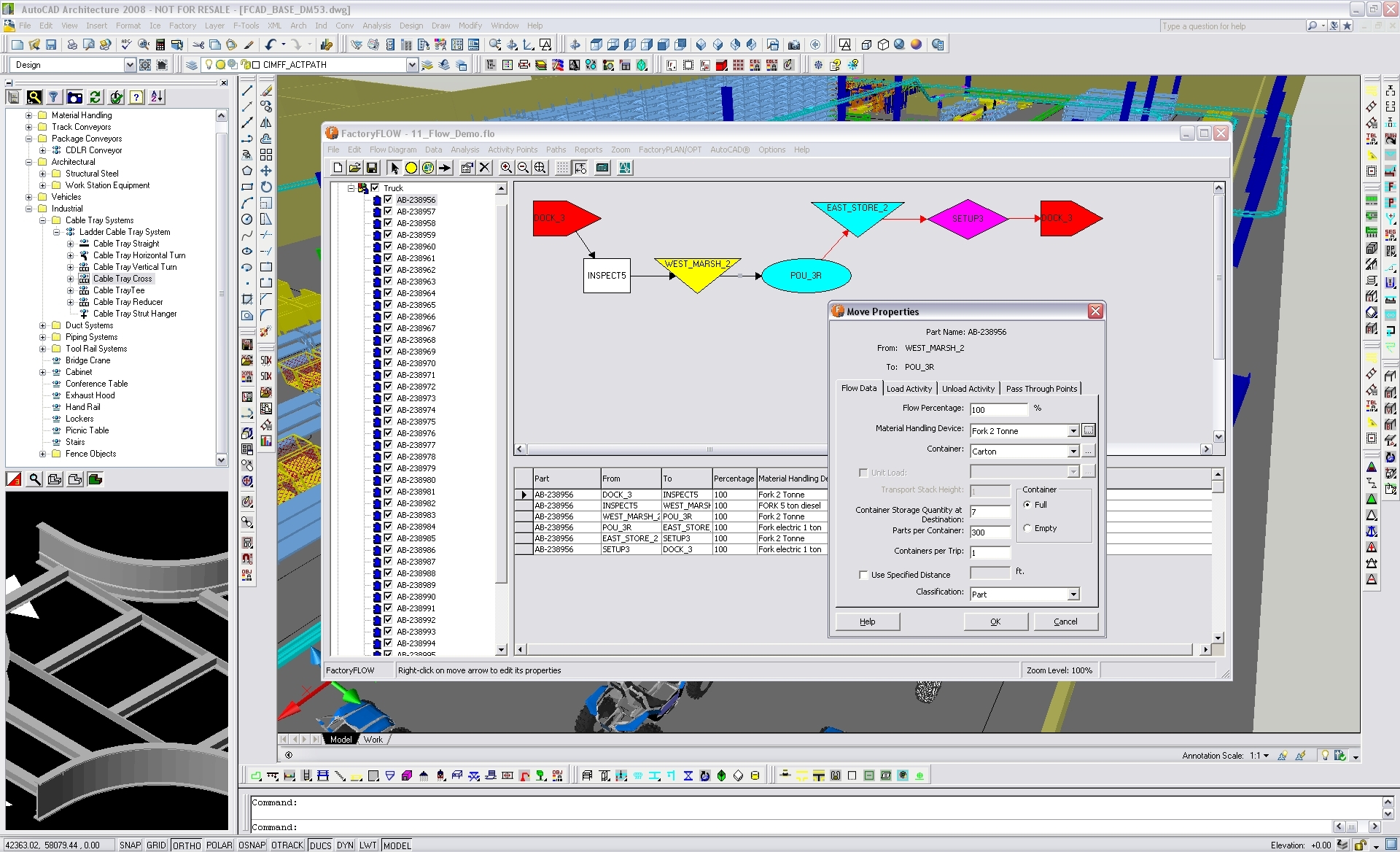

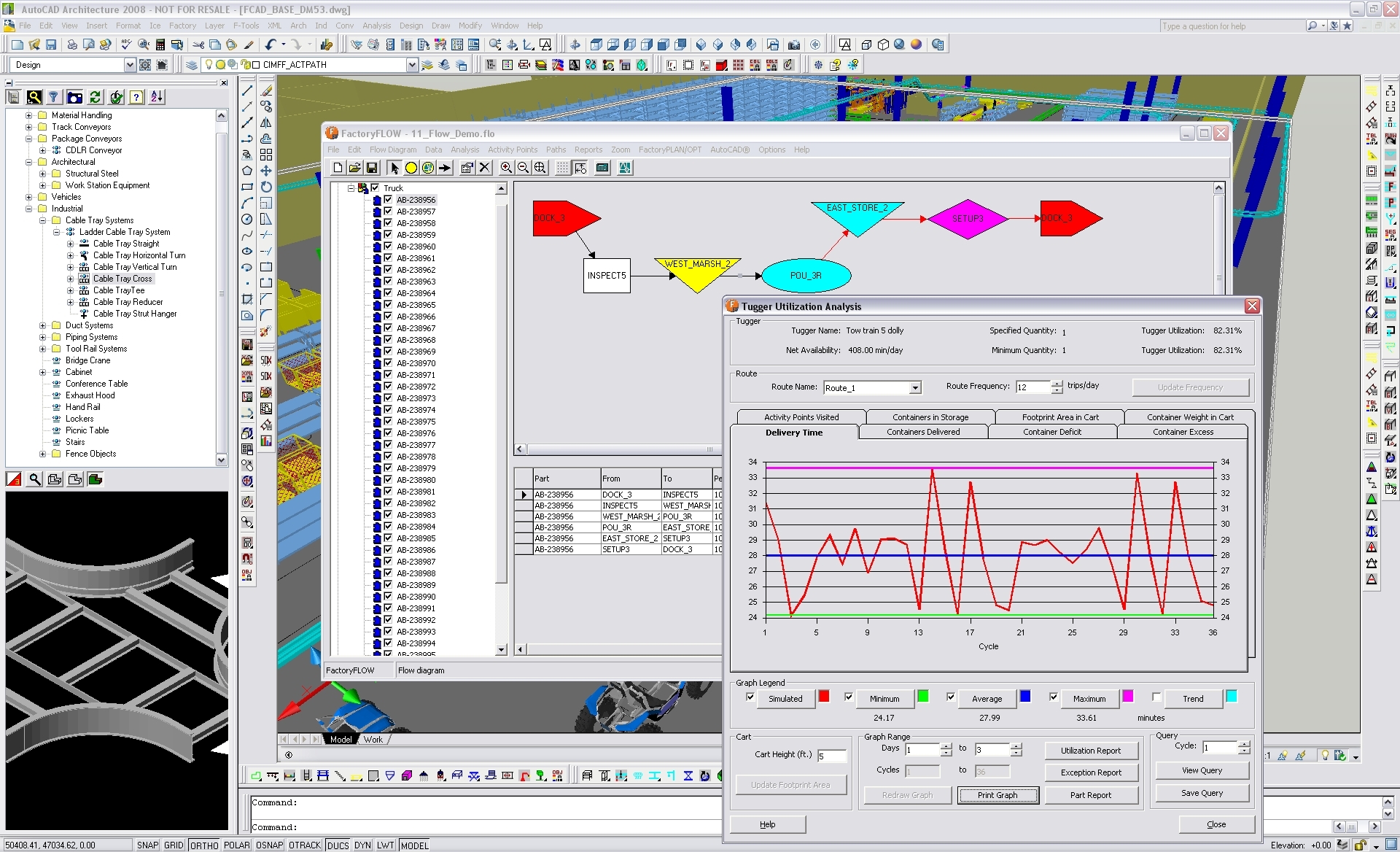

Tecnomatix FactoryFLOW is a graphical material handling system that allows your industrial engineers to optimize a factory layout based on material flow distances, frequency and cost. This is accomplished by evaluating and analyzing things like part routing information, material storage needs, material handling equipment specification and part packaging (containerization) information against the factory layout.

Using FactoryFLOW, you will create efficient factory layouts with reduced part travel distances, lot sizes, and inventory levels as well as improved communications and throughput – all of which drive towards decreased manufacturing costs and increased production efficiency.

Capabilities

- Create Material Flow and Congestion Diagrams

- Compute Material Handling Equipment Requirements

- Analyze and Validate Operator Walk-Paths

- Build Tugger Routes based upon Material Requirements

- Design Packing Strategies for Storage Areas and Transport Vehicles

Benefits

- Reduced material handling costs

- Optimized space utilization of shop floor storage areas

- Reduce non-value added work and minimize indirect labor costs

- Optimized resource utilization and material flow

- Optimized material packing for transportation vehicles