Plant, Line & Process Simulation & Optimization

In times of increasing cost and time pressures in production, along with ongoing globalization, logistics has become a key factor in the success of a company. Money can be lost daily through inefficient schedules, local instead of global optimization, inefficient resource allocation, and poor productivity. The need to deliver just-in-time (JIT) / just-in-sequence (JIS), introduce Kanban, plan and build new production lines and manage global production networks requires objective decision criteria to help management evaluate and compare alternative approaches.

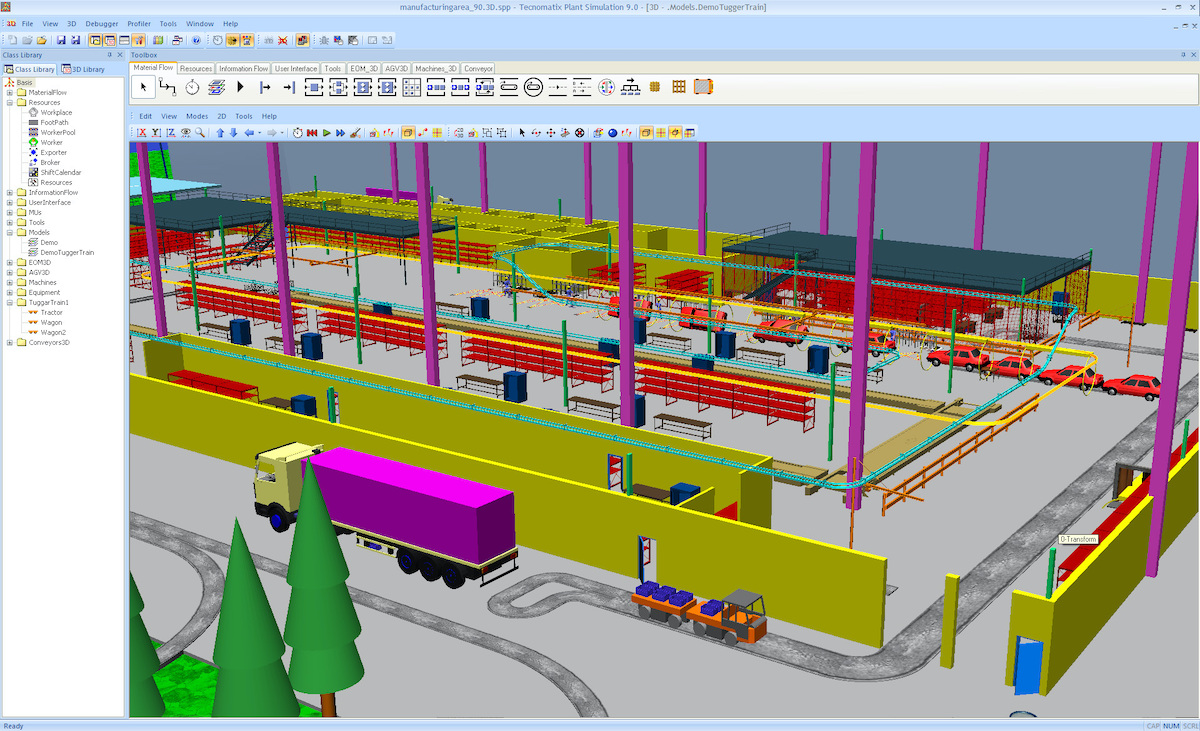

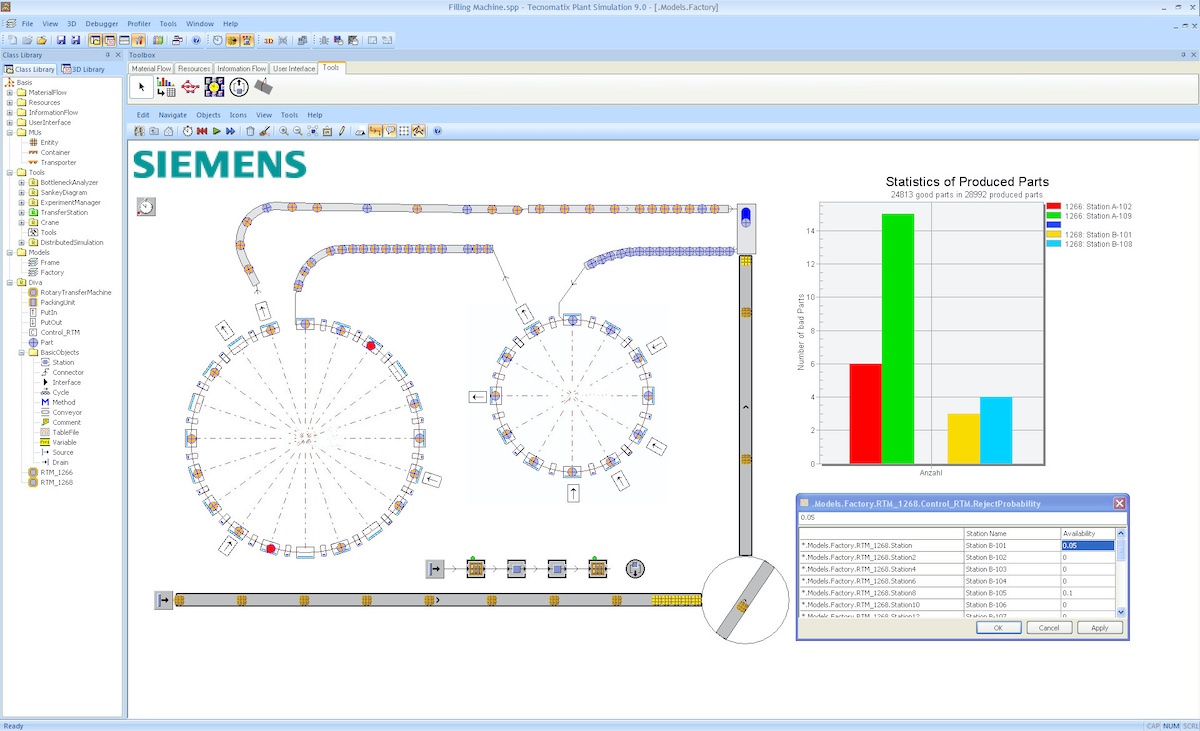

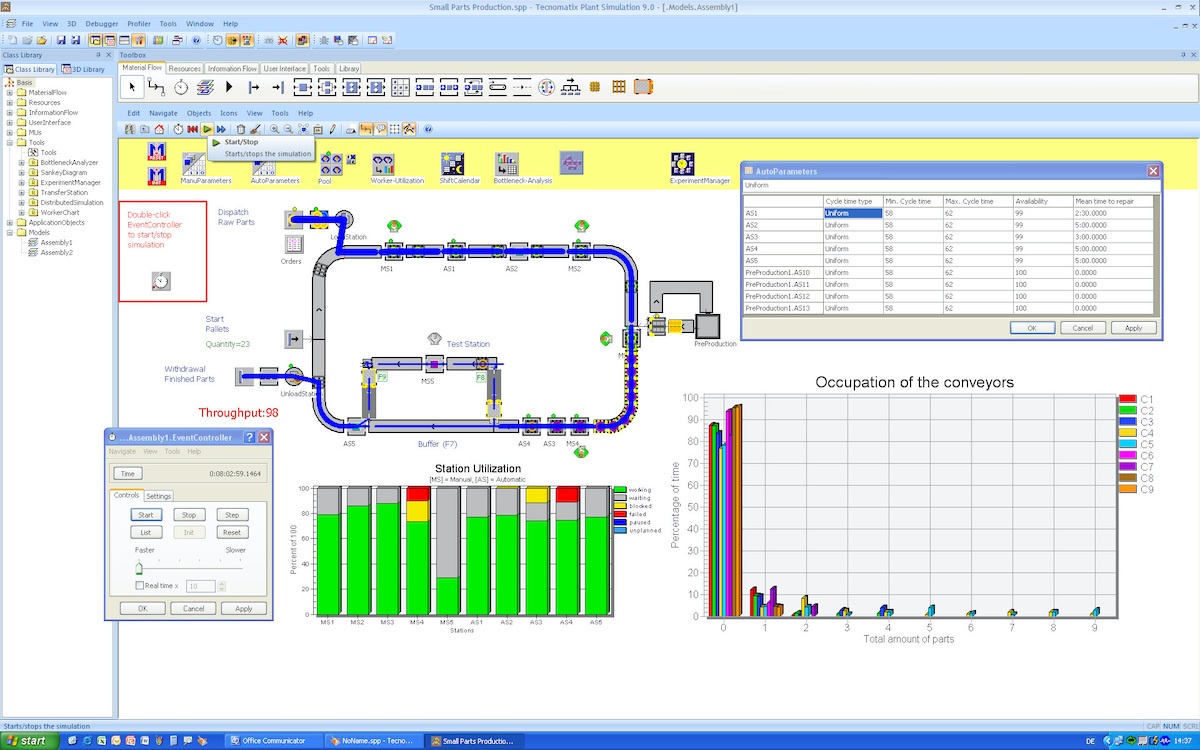

Tecnomatix Plant Simulation is a discrete event simulation tool that helps you to create digital models of logistic systems (e.g., production), so that you can explore the systems’ characteristics and optimize its performance. These digital models allow you to run experiments and what-if scenarios without disturbing existing production systems or – when used in the planning process – long before the real production systems are installed. Extensive analysis tools, such as bottleneck analysis, statistics and charts let you evaluate different manufacturing scenarios. The results provide you with the information needed to make fast, reliable decisions in the early stages of production planning.

Using Plant Simulation, you can model and simulate production systems and their processes. In addition, you can optimize material flow, resource utilization and logistics for all levels of plant planning from global production facilities, through local plants, to specific lines.

Capabilities

- Object Oriented Models with Hierarchical Structure

- Open Architecture with Multiple Standard Interfaces

- Library and Object Management

- Genetic Algorithm Driven Optimization

- Automatic Analysis of Simulation Results

- HTML based Report Builder

Benefits

- 3-6% Savings upon Initial Investment

- Increase Existing System Productivity 15-20%

- Reduce New System costs 5-20%

- Optimize Resource Consumption and Re-Use

- Reduce Inventories 20-60%

- Reduce Throughput Time 20-60%

Interested in this solution?

Plant Simulation (365kb PDF)

Plant Simulation Assembly Library (287kb PDF)

Plant Simulation For Shipyards (164kb PDF)

Plant Simulation For Warehousing and Logistics (377kb PDF)

Plant Simulation Shop (406kb PDF)