Planning Productivity

Accelerate your manufacturing planning by up to 40% without sacrificing quality. Tecnomatix empowers your team with integrated planning solutions that deliver instant access to the latest product data. Capture, standardize, and re-use best practices to eliminate waste, shorten development cycles, and ensure repeatable, high-quality results. Automated validation tools help you reduce errors and free your team from time-consuming tasks so they can focus on innovation.

Manufacturing Productivity

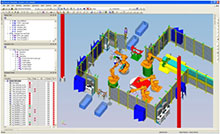

Tecnomatix 9 revolutionizes how manufacturers approach productivity—optimizing everything from robotics and automation commissioning to manual workplace design and material flow efficiency. With advanced simulation and validation tools, you can virtually optimize your production lines before construction begins. The result? Higher throughput, greater safety, lower costs, and reduced capital investment—all before a single machine hits the factory floor.

Tecnomatix Capabilities

- Harness the full power of Tecnomatix with solutions designed to optimize every stage of your manufacturing process:

- Part Planning & Validation – Ensure manufacturability before production starts.

- Assembly Planning & Validation – Simulate and validate assembly processes for efficiency and accuracy.

- Robotics & Automation Planning – Optimize robotic paths, programs, and performance virtually.

- Plant Design & Optimization – Model and configure layouts to improve flow and resource use.

- Quality Management – Integrate quality checks into planning to reduce errors and defects.

- Production Management – Balance resources, processes, and capacity for maximum output.

- Manufacturing Process Management (MPM) – Control and standardize processes across global operations.

Why Choose Tecnomatix?

- 40% faster planning cycles

- Reduced costs and downtime with early virtual validation

- Improved product quality through repeatable, standardized best practices

- Scalable solutions for robotics, automation, and manual processes

With Tecnomatix, you don’t just plan for productivity—you engineer it into every step of your operation.

Tecnomatix Solutions

- Tecnomatix FactoryCAD

- Tecnomatix FactoryFlOW

- Tecnomatix Plant Simulation

- Tecnomatix Process Simulate

- Tecnomatix Process Simulate Human

- Tecnomatix RobCAD

Brochures and White Papers

Siemens PLM Tecnomatix Overview

Tecnomatix 10 Release – What’s New Fact Sheet

Siemens PLM Tecnomatix Plant Design and Optimization Solution Fact Sheet

Connecting Manufacturing Engineering and the Shop Floor

Take the Next Step

Ready to transform your planning and production? Discover how Tecnomatix can help you increase efficiency, reduce risk, and achieve faster time-to-market.

Contact us today to schedule a demo and see Tecnomatix in action.