Smarter Planning for a Competitive Edge

In today’s global manufacturing environment, rising costs, compressed timelines, and complex supply chains put increasing pressure on production efficiency. Lost productivity, inefficient schedules, poor resource allocation, and fragmented optimization can cost companies millions each year.To stay competitive, manufacturers must embrace data-driven decision-making—whether planning new production lines, introducing lean practices like Just-in-Time (JIT) and Just-in-Sequence (JIS), or managing global production networks.

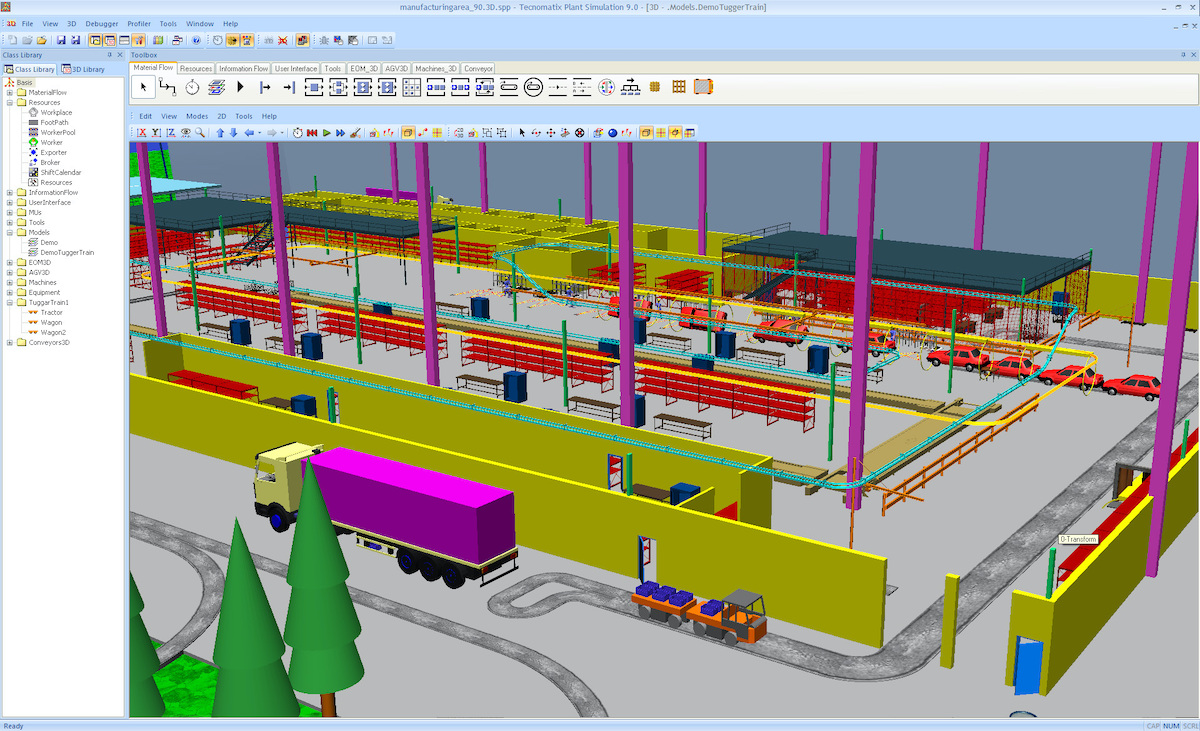

What is Tecnomatix Plant Simulation?

Tecnomatix Plant Simulation is a powerful discrete-event simulation software that enables you to create digital twins of production systems and logistics operations. With these digital models, you can:

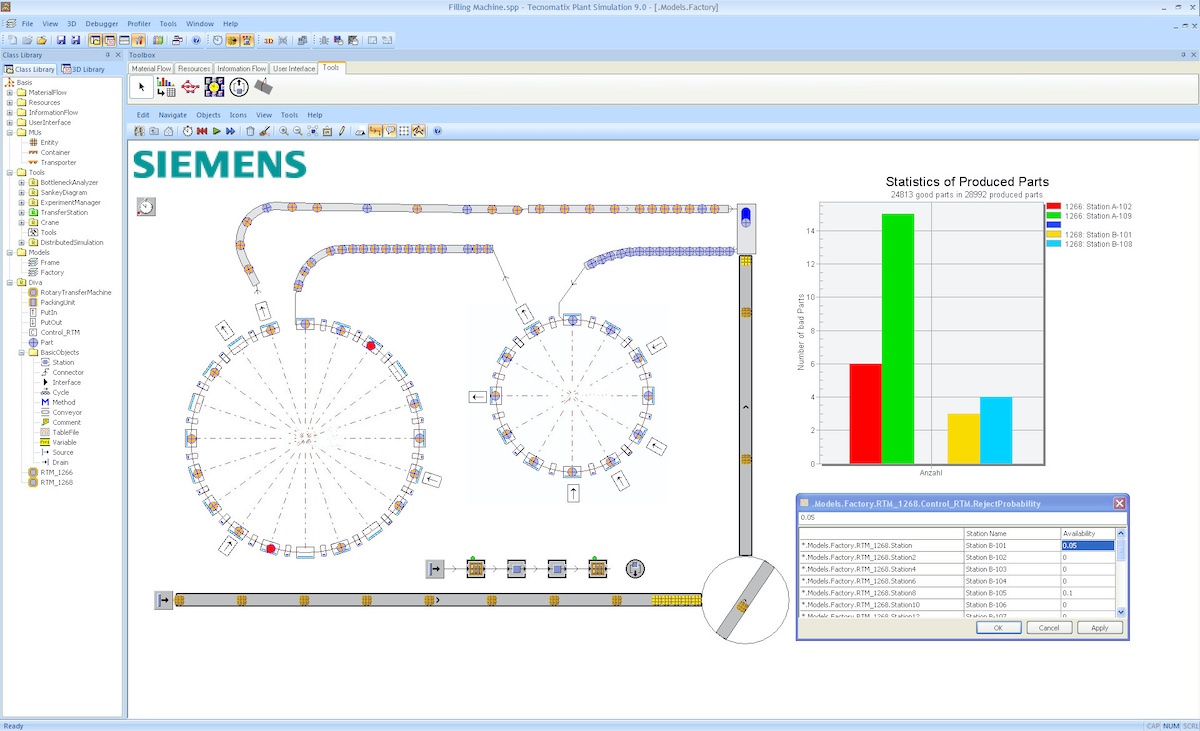

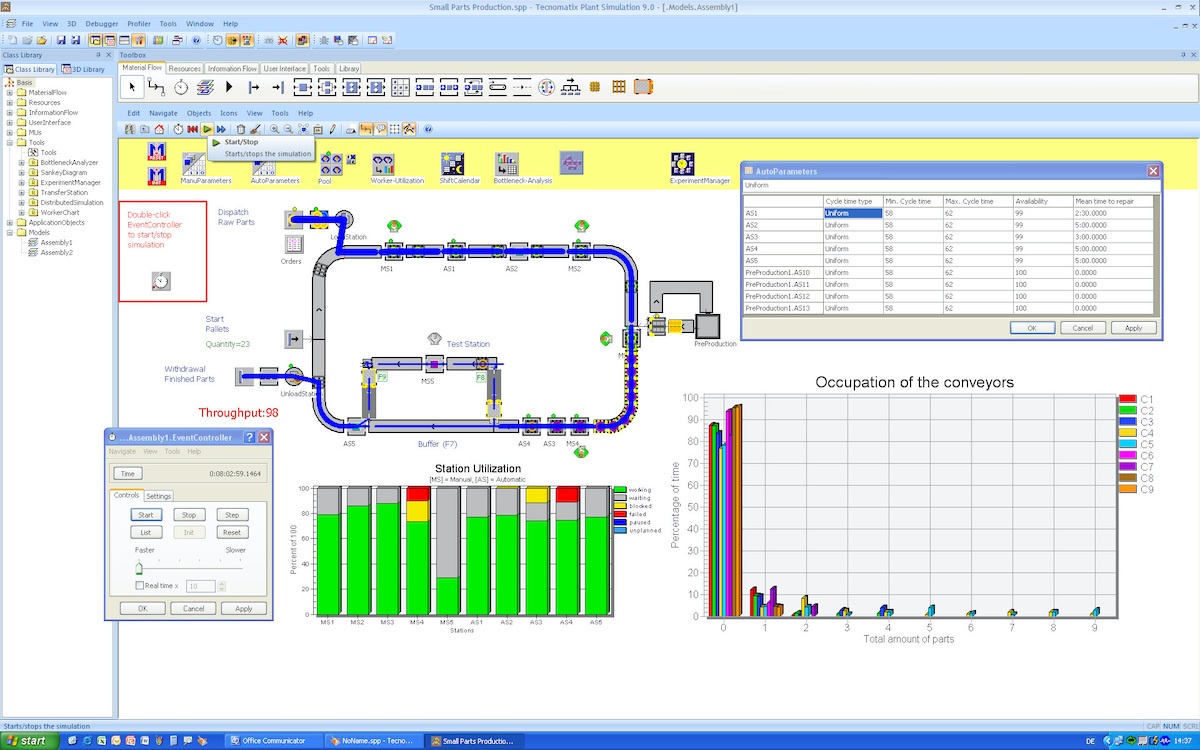

- Run experiments and what-if scenarios without disrupting live operations.

- Optimize performance in advance—long before physical systems are built.

- Identify and eliminate bottlenecks with advanced analysis tools.

- Make faster, smarter decisions using real-time statistics and scenario comparisons.

By simulating processes before implementation, you reduce risk, lower costs, and ensure your production systems are optimized for speed, quality, and profitability.

Key Capabilities

- Object-Oriented Modeling with Hierarchical Structures – Build scalable, modular simulations that mirror your operations.

- Open Architecture with Standard Interfaces – Integrates seamlessly with ERP, MES, and PLM systems.

- Extensive Libraries and Object Management – Speed up model creation and standardization.

- AI & Genetic Algorithm Optimization – Automatically discover optimal configurations for complex systems.

- Automated Data Analysis – Generate statistics, bottleneck reports, and KPIs instantly.

- HTML-Based Report Builder – Share results easily across teams and management.

Business Benefits

Plant Simulation isn’t just about modeling—it’s about delivering measurable results across your manufacturing network:

- 3–6% savings upon initial investment.

- 15–20% increase in existing system productivity.

- 5–20% reduction in new system costs.

- 20–60% reduction in inventory levels.

- 20–60% shorter throughput times.

- Optimized resource usage and improved sustainability.

From Global Networks to Local Lines

Tecnomatix Plant Simulation supports all levels of planning—from global supply chains to individual production lines. Whether you’re:

- Designing a new factory layout,

- Optimizing logistics for a global production network, or

- Improving material flow in a single line,

Plant Simulation provides the visibility and confidence you need to make the right decisions, faster.

Why Choose Tecnomatix Plant Simulation?

- Proven ROI across industries.

- Reduced risk with early validation.

- Increased agility to adapt to new market demands.

- Tools to standardize best practices across your organization.

With Tecnomatix, you can turn complexity into competitive advantage by aligning production efficiency with business goals.

Take the Next Step

Ready to optimize your plant and production systems? With Tecnomatix Plant Simulation, you can eliminate waste, cut costs, and maximize output—before your systems are even built.

Contact us today to schedule a demo and see how Plant Simulation can transform your operations.

Get Started

Interested in this solution?

Product Documentation

Plant Simulation (365kb PDF)

Plant Simulation Assembly Library (287kb PDF)

Plant Simulation For Shipyards (164kb PDF)

Plant Simulation For Warehousing and Logistics (377kb PDF)

Plant Simulation Shop (406kb PDF)