3D Manufacturing Process Verification for Faster, Smarter Production

Modern manufacturers face intense pressure: reduced time-to-market, higher quality standards, and tighter budgets. Successful product launches depend on the ability to design, validate, and optimize processes before production begins. That’s where Siemens Technomatix Process Simulate makes the difference.

With Process Simulate, you can virtually plan, simulate, and verify every aspect of your manufacturing process — from human tasks to robotic automation — in a powerful 3D environment. By identifying inefficiencies and validating processes upfront, your team saves time, reduces costs, and achieves more reliable production launches.

Why Process Simulate?

- Accelerate Time-to-Market – Validate processes virtually and reduce costly physical prototypes.

- Boost Productivity & Quality – Ensure error-free assembly, robotics, and automation before production.

- Reduce Risk – Detect collisions, test ergonomics, and optimize cycle times in a digital twin.

- Lower Costs – Minimize downtime, material waste, and commissioning issues.

Explore Process Simulate Capabilities

Learn more about the dedicated tools available that make your modeling and simulation tasks easier and that provide additional value to your Process Simulate investment.

Assembler

Design, analyze and verify product assembly and disassembly processes to determine the most efficient, collision-free sequence in the shortest amount of time.

Use Process Simulate Assembler for modeling, dynamic creation and simulation of assembly and disassembly paths and operation sequences, collision detection and clearance assessment, 2D and 3D sectioning and measurement analyses. Select the most suitable tool for the operation, perform virtual clearance tests and collision analysis, and simulate the complete process of the product and the tool together.

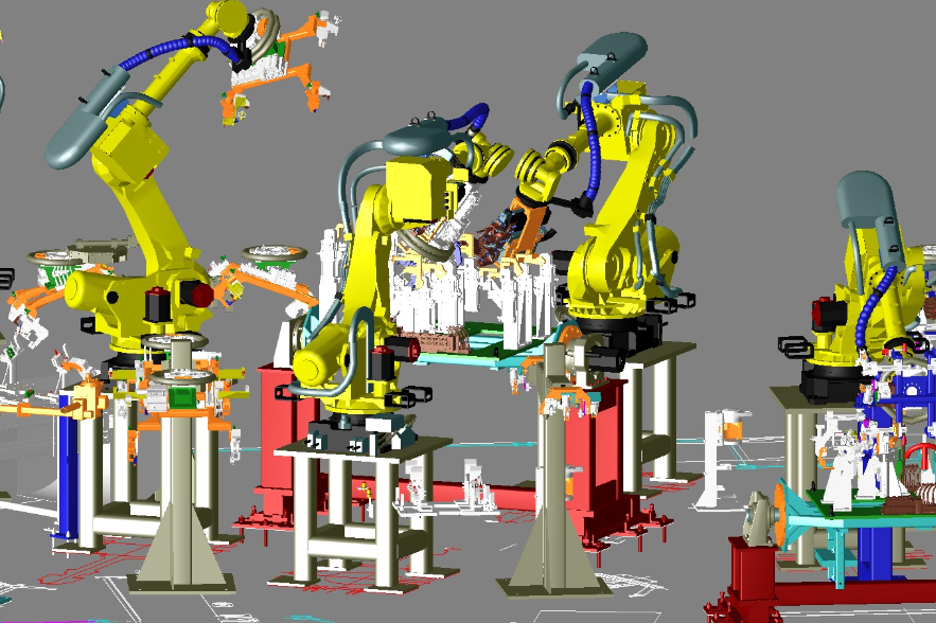

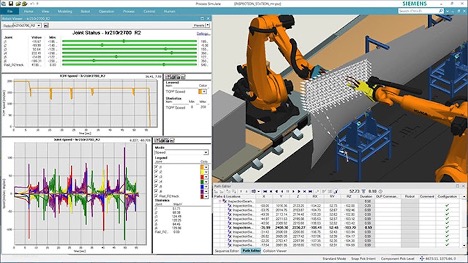

Robotics

Conduct virtual development, simulation and commissioning of robotic and automated manufacturing systems, including highly automated plants with a variable production mix.

Use Process Simulate Robotics to facilitate collision-free robot motion path planning and simulation, automatic robot placement and reach testing, robotic operation cycle time and energy usage optimization, and simplification of the process for synchronizing multi-robot workstations and zones. Multiple engineering disciplines can use the software to plan and validate manufacturing systems that range from single workstations to complete production lines.

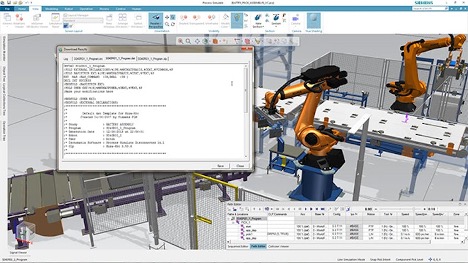

OLP — offline programming

Maintain and optimize robotic processes in a dynamic 3D virtual environment without interrupting existing production.

Use Process Simulate Offline Programming (OLP) for the creation and manipulation of robot-specific target locations, orientation, configuration, motion paths and interference zones. Perform cycle time optimization, configurable motion and OLP command creation and editing, robot calibration, and complete robot program download and upload based on the robot teach pendant interface and the robot controller for all major robot brands.

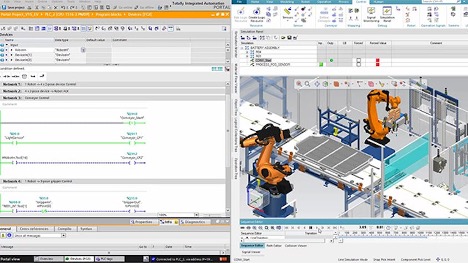

VC Lite — virtual commissioning

Perform virtual commissioning (VC) with offline Process Simulate models, including layout creation, kinematics definitions, simulation and analysis.

Use Process Simulate VC Lite to validate and optimize the build, installation and commissioning (mechanical and electrical) of manufacturing zones or cells containing robots and other automation devices. Simulate real programmable logic controller (PLC) code with the hardware using Siemens TIA Portal and PLCSIM Advanced software or OPC UA software and the actual robot programs, providing the most realistic virtual commissioning environment.

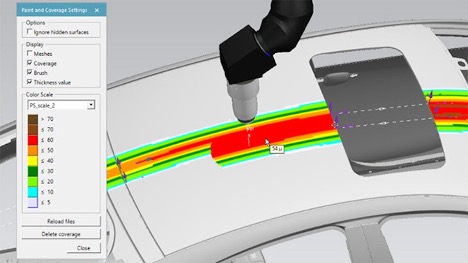

Continuous Manufacturing

Develop robotic manufacturing processes with tools for weld seam creation and continuous path generation for gluing, sealing and spraying operations, full robot motion path simulation and optimization for robot placement, reach and cycle time.

Use Process Simulate Continuous Manufacturing to import weld seams and machining toolpaths for robot path creation, to generate weld seams and continuous motion paths based on curves and geometry recognition, to align path locations based on surface-normal conditions, and to simulate paint and spray coverage and thickness.

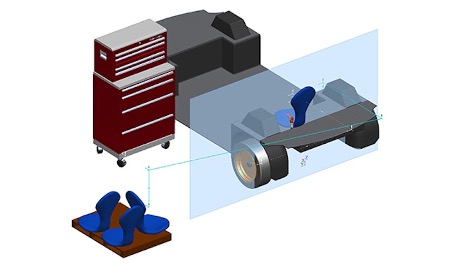

Human Simulation

Design, analyze and optimize detailed human operations by scaling virtual human figures to fit any worker population for any task simulation.

Use Process Simulate Human to verify the design of a workstation, ensuring that product parts can be reached, assembled and maintained. Analyze and optimize the cycle time and ergonomics of the human operation and workstation, ensuring a safe process according to industry and corporate standards.

VR Analyze — virtual reality

Load Process Simulate studies into virtual reality (VR) environments to conduct design and process reviews, perform analysis of the scene and simulation and collaborate while fully immersed using VR hardware provided by HTC and HP.

Use Process Simulate VR Analyze to move within the virtual environment, play, pause and reset simulations created in Process Simulate, manipulate robots within the scene, make measurements, and record notes and markups.

The Bottom Line

Technomatix Process Simulate helps you launch products faster, cut costs, and ensure flawless production by leveraging the digital twin of your manufacturing processes. From concept to continuous improvement, Process Simulate empowers engineering teams to stay ahead of today’s toughest manufacturing challenges.

Streamline Your Process Design Today

Contact us to learn how Process Simulate can help your team accelerate innovation and deliver manufacturing excellence.