What Is Plant Simulation in Manufacturing?

March 1, 2022

Siemens NX Training

June 23, 2022Siemens NX, or Unigraphics NX, is a Siemens PLM software offering a wide range of robust and flexible integrated tools for the faster and more efficient delivery of products. These design, manufacturing, and simulation solutions allow your company to optimize the digital twin value of systems and products, minimizing physical prototyping costs.

Siemens NX provides support for every stage of the product development process, including concept design, generative engineering, and manufacturing. The enhanced Synchronous Technology that Siemens NX delivers is instrumental in flexible assembly and component modeling. This technology also offers multi-CAD capability while streamlining digital simulations.

NX offers the broadest range of CAD/CAM/CAE applications in the industry. The software’s integrated process automation tools allow your company to record and reuse knowledge to develop best practices for optimal efficiency and profitability.

To implement Siemens NX into your operations, contact our team at 4D Systems today. As an authorized Siemens reseller partner, we can provide you with a custom Siemens NX solution that fits your project requirements.

What Is NX Used For?

Your manufacturing plan or design company can use Siemens NX for a wide range of applications:

Design and Styling

Siemens NX offers a comprehensive range of design features you can use to create digital twins of product prototypes, ensuring optimal aesthetics and functionality. The tooling and fixture design feature is an automated virtual solution for streamlining development processes. In addition to product prototypes, you can also use NX to design product packaging and electromechanical systems.

Mechanical Simulation

You can simulate a product design in a realistic virtual setting with the mechanical simulation feature. This feature saves valuable time and costs, as you don’t need to make multiple physical prototype adjustments.

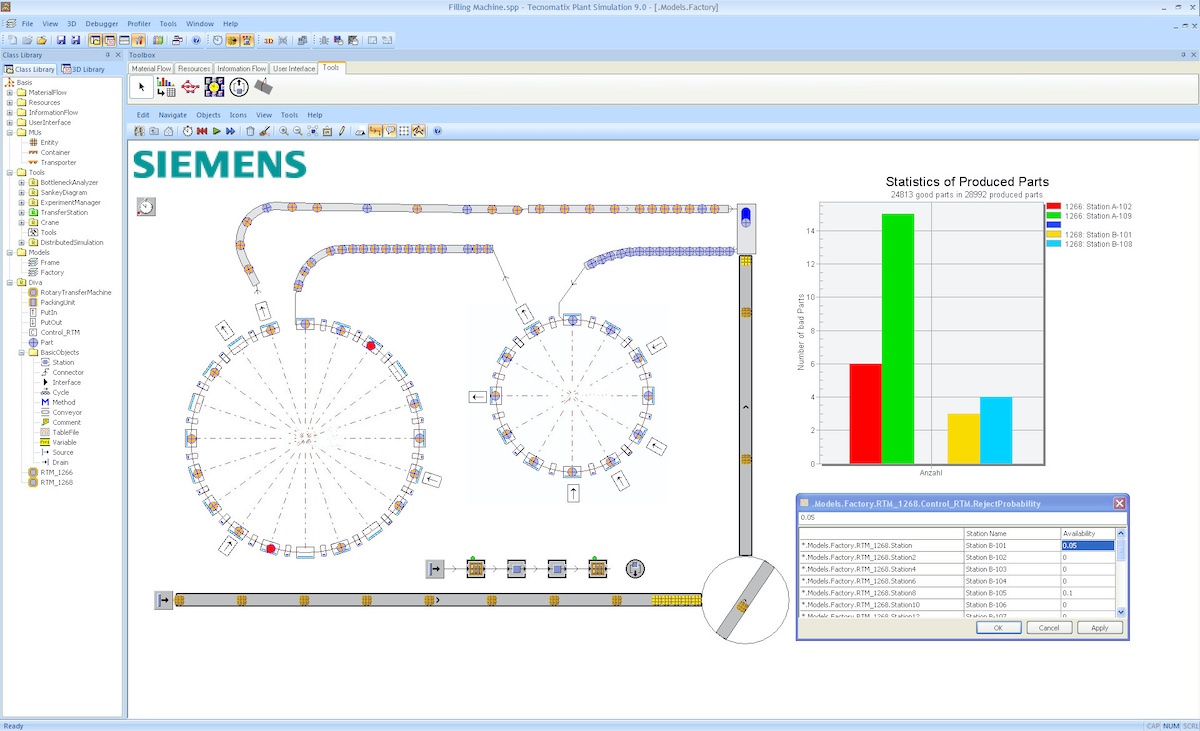

Engineering Process Management

NX’s engineering process management functionality lets you consolidate your engineers’ operations and manufacturing systems within one digital environment. Using this tool, you can monitor progress, ensure seamless collaboration between teams, and coordinate the process’s architecture, ensuring optimal efficiency and cost savings.

Machining

The machining feature incorporates digital precision solutions, making optimal manufacturing efficiency possible. Using this solution, you can:

- Program CNC machine tools

- Operate 3D printers

- Carry out quality control

- Manage robotic cells

Automating these operational tasks will streamline machining while ensuring the optimal allocation of your company’s human resources.

Who Uses Siemens NX?

Ford Motor Company

The American multinational vehicle manufacturer, Ford Motor Company, uses Siemens NX with PMI, facilitating a multi-dimensional 3D annotation environment. Employing NX allows Ford to improve powertrain component manufacturing while reducing costs.

General Motors

General Motors uses a wide range of Siemens PLM Software solutions, including Siemens NX. The applications of this software in General Motors’s operations include computer-aided design, engineering analyses, and manufacturing.

Mazda

Mazda implements several Siemens PLM solutions into its research, design, and manufacturing processes. These integrated tools include Siemens NX for enterprise collaboration, streamlining Mazda’s operations across the product development process.

SpaceX

SpaceX designers use Siemens NX for the entire design of their rockets. After loading a virtual mock-up of the rocket, designers use this software to locate interferences. SpaceX shop floor technicians also use NX models to gain insights into the rocket’s inner mechanisms.

SpaceX designers use Siemens NX to ensure that their rocket designs are fully functional by simulating motion.

Raytheon

Raytheon Space and Airborne Systems deploys NX products across multiple programs. One of these programs is the simulation and validation of advanced high-energy laser systems. Using NX, engineers can evaluate these systems’ structural thermal and optimal performance.

Should I Learn CATIA or NX?

CATIA is a CAD application suite providing design, manufacturing, and engineering solutions. This software helps you navigate the complete design process, from conceptualization to manufacturing. CATIA’s functionalities make it a viable option for mechanical engineers, electrical designers, fluid and systems engineers, and builders.

Choosing between CATIA and NX can be challenging. This section looks at some of the most significant differences between the two applications.

CATIA is a relatively expensive subscription-based software with perpetual licensing. NX is more affordable with subscription-based licensing. CATIA is compatible with Unix and Windows operating systems, while NX offers Unix, Windows, and Mac compatibility.

NX has a modern but straightforward interface that is highly intuitive and easy to learn. CATIA’s interface is somewhat more challenging to navigate. Both NX and CATIA have free trials which you can use to determine which solution is best for your needs and capabilities.

Another significant difference between CATIA and NX is that the former offers collaboration by connecting with the 3D Experience platform. On the other hand, NX uses Teamcenter integration as a collaboration solution.

Siemens NX’s integration solutions for CAD and CAM are also superior to CATIA. If you want to use specific CAM functions using CATIA, you need to run third-party applications.

Thanks to its high-end surface modeling tools, CATIA is ideal for the automotive industry. This functionality in NX is not as effective. However, with Siemens NX, you get other high-value toolsets, including the software’s CAM.

Is The Software Hard to Learn?

No, Siemens NX is one of the more straightforward product development solutions to learn, especially if you have a background in CAD software. The NX interface is easy to navigate, and most designers will find this software intuitive.

The availability of free online information also makes Siemens NX easy to learn. If you have difficulty with the software, you can reach out to one of our team members at 4D Systems to learn more about our Siemens NX training solutions.

Contact 4D Systems

At 4D Systems, we are a leading provider of Siemens PLM software, including NX. Our engineering team has extensive experience in product lifecycle management solutions, including design, engineering, and manufacturing.

Our objective is to provide you with a competitive edge in the market by outputting high-quality products faster while saving valuable time and money.

Do you want to implement a comprehensive digital product development solution into your operations? Our team at 4D Systems will provide you with a custom Siemens NX solution that fits all your project requirements. Please contact us today at (800) 380-9165 or by email at [email protected].