CATIA V5 Composites Manufacturing Preparation

Overview

Companies are facing the challenges of developing complex production-ready composite design and mass-producing composite parts. In order to overcome these challenges, manufacturing and engineering need to efficiently collaborate throughout the product development process.

The CATIA – Composites Manufacturing Preparation option provides a completely CATIA integrated environment dedicated to manufacturing detailed design of composite parts, enabling engineers to include all manufacturing constraints early in the composites design process. With powerful synchronization capabilities, this option is the essential link between engineering design and physical manufacturing.

Benefits

- Fully integrated in the V5 environment

- Management of the manufacturing parameters at the early stages of the design process

- Easy collaboration between design and manufacturing office enabling concurrent engineering

- Strong manufacturing partnerships ensure that composites solution can be used by any company, regardless of the manufacturing process and machine providers

Capabilities

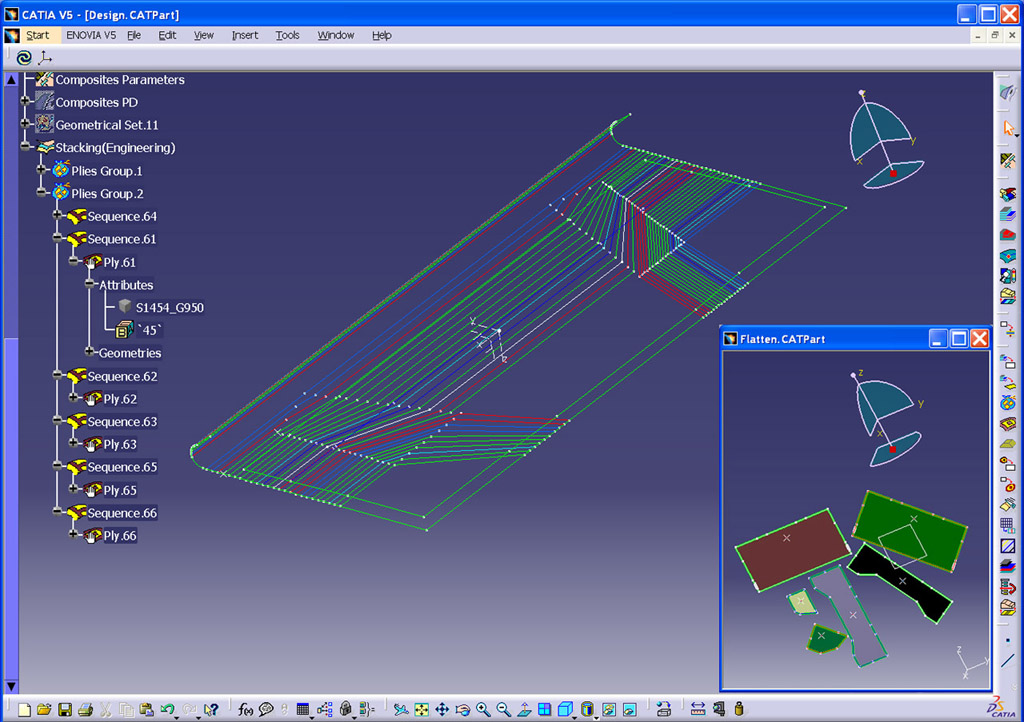

- Dedicated manufacturing part modeling capabilities such as manufacturing shell swapping, material excess definition and 3D multi-splice

- Best-in-class fiber simulation and flattening tools for early assessment of manufacturability

- Effective manufacturing export capabilities and automatic shop floor documentation

- Powerful synchronization/collaboration mechanisms with engineering detailed design

Workbenches

This option contains:

CATIA – Composite manufacturing

CATIA – Generative Shape Design 2

Interested in this solution?