What is Catia?

September 12, 2021

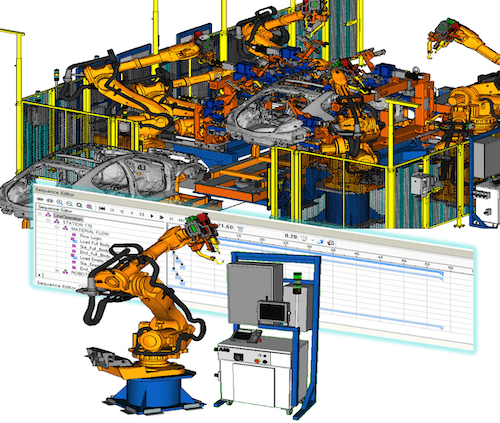

Siemens Process Simulate Builds Efficient Assembly Lines

December 28, 2021The words “robotic systems” conjure up many images. However, if you automatically think “job losses,” you won’t be alone, but it couldn’t be further from the truth: 4D Systems puts humans and robots together to benefit employees, companies, industry, and the world.

Founded in 2010 in Flint, Michigan, the 4D Systems team operates largely in North and South America, where it provides new abilities and resources for its customers through a variety of services such as robot programming, simulation, controls, and design.

This A3 certified robotic integrator specializes in the creation of custom robotic work cells using multiple layouts and solutions for numerous applications including spot welding, material handling, vision, blasting, painting, cutting, sealing, and thermal processing.

Designing and building turn-key robotic systems out of its impressive 10,000-square-foot shop, the team installs and supports these for customers across the continent.

Using years of robotic experience developed through R&D, the company sets its 70-plus highly-skilled engineers to work with manufacturers everywhere, designing work cells for production needs. Though the team is more than capable of handling multi-million-dollar projects – and can work with any existing robotic system – an important element for 4D Systems is attention to those companies with smaller requests.

Small is specialized

“We don’t compete with the big companies. We do smaller, spe-cialty work,” says President and Owner, JP Rasaiah. “We have great customer service, and we believe in helping compa-nies who don’t know where to start. Where we really excel is complex tasks and helping with little projects that companies may think are too expensive, but actually may not be.”

“Companies that look to 4D Systems for guidance will find everything they need, from a price that fits to a finished product that meets their needs.”

A certified integrator for FANUC, ABB, Yaskawa and Kawasaki, and specializing in the creation of custom robotic work cells, 4D Systems provides automation solutions for the automotive, oil and gas, aerospace, consumer, defense and medical indus-tries, to name a few, employing innovative and competitive solutions to help increase market profitability and productivity via its world-class process, workflow, and asset management.

“A company comes to us and says, ‘We need help, we need a robot,’ and 4D Systems works from A to Z,” says Rasaiah. “We help right from the preplanning stages, at the very end or in between. Automation doesn’t have to be expensive. It can be scaled to meet most budgets.”

It is those smaller needs and requests that 4D Systems has made its area of expertise, the projects that larger companies may find not worth their time or effort.

Suite of services

4D Systems boasts an impressive suite of robotics and auto-mation services including turnkey specialty systems, building and installing automated robotic systems, robotic and human simulation software, PLM (product lifecycle management) software, robot programming, controls programming, simula-tion services, mechanical design services, and laser scanning pre and post integration. Such a full bouquet of services allows the team to provide outstanding quality and options to clients.

Rasaiah is particularly proud of the company’s exhaustive famil-iarity with its software, enhancing its ability to help companies at every step, from start to finish.

“It’s the same software we use in our products, which we use and know well,” he says. “Being familiar with it gives us an edge. We sell and support the software. We know all the software, so we know it works and can assist customers when needed.”As leaders in all aspects of the PLM cycle, including CAD concept, data management, manufacturing planning, manufacturing improvements, simulation, work instructions, and project man-agement and disposal, Rasaiah says that 4D Systems “does a lot of things,” all while working and interacting as a team and handling any challenges that may arise.

“We’re a team that works well together and overcomes obsta-cles which is really important,” says Rasaiah. “We constantly learn from the mistakes of other organizations, which helps make us better. We listen to others and learn, because we want to grow and improve our quality for customers.”

Full simulations

While continuing to grow its specialty robotics field, 4D Systems is still committed to performing full simulations.

“A lot of companies only do partial simulations, not full,” he says. “We simulate properly and make sure every aspect is working right. We laser scan a lot of things beforehand and put every-thing together to make sure it all fits perfectly.”

This commitment to customer service is what makes 4D Systems stand out from its competition, along with the ability of the talented engineering team to create turn-key solutions.

“Most of our engineers are trained in multiple disciplines,” says Rasaiah. “Mechanical, robot programming, controls and simulation. This gives them the ability to understand other phases of turn-key that they may not be responsible for but have to work with.”

Using the best software to design, verify and execute its robotic systems means 4D Systems can pass along the absolute best results to customers.

“We incorporate laser scanning pre and post,” says Rasaiah. “That way we design something that works the first time. Other companies design systems only to find out the system doesn’t fit, or the robot cannot reach properly. Our integrated approach keeps this from happening, preventing time and cost overruns which can be very costly as related to time to market.”

Expanding interests

4D Systems has also diversified into other fields of interest, includ-ing aerospace and defense, and work with the U.S. Government.

“Robotics have been widely adopted by automotive for decades, but it’s not as easy to be adopted by aerospace and defense due to regulations,” explains Rasaiah. “Currently the aerospace and defense sectors are using more and more robots. We’ve been involved with projects involving robotics at Hill AFB, Tinker AFB and we’ve sold software to Holloman AFB.”

With the ability to supply companies with the additional manpower required to achieve their various objectives, the company’s robot programmers and controls engineers not only help customers meet production and automation goals, but also help with employee support and training.

“We understand the software. We know software. We sell it and we cross-train a lot,” says Rasaiah. “All our people are cross-trained which is important. Our people have multiple disciplines.

The company’s dedication to lean manufacturing processes also shows its commitment to eco-awareness and reducing waste in its processes. Cutting potential environmental waste is a vital aspect of robotics that many may not understand.

As an example, Rasaiah describes how robots were used – instead of the variable skills of humans – to properly and pre-cisely install automotive sun-roofs and avoid leaking, costly repairs, and unrecyclable waste, all of which have been issues in the past.

“Some things are too hard to reuse and repurpose for envi-ronmental issues, so robotics can make it better the first time around,” says Rasaiah. “And as for potential health issues, auto plants, for instance, can be physically dirty and unhealthy, so it’s good to have robots there doing those jobs instead of humans.”

Utilizing lean practices for companies is of utmost impor-tance on a global stage where eliminating as much manu-facturing waste as possible is the best way to fight envi-ronmental damage. Robotics and digital manufacturing are beneficial both ecologically and economically and will continue to grow in a variety of manufacturing sectors.

4D Systems is constantly innovative in its practices, with an eye to helping customers meet their goals right now, while also being aware of the importance of long-term business plans.

Spurred by challenge

As with most companies, dealing with the pandemic this past year-and-a-half has created many a challenge for 4D Systems to deal with.

“There are obstacles to overcome on every project,” says Rasaiah. “But delays due to market uncertainty because of COVID are the biggest. However, I think the industry has mostly gone past that obstacle by adopting protection guidelines.”

“A company says, ‘We need help, we need a robot,’ and 4D Systems works from A to Z. It doesn’t have to be expensive. A lot of companies don’t know this until they talk to us.”

Rasaiah is quick to credit the 4D Systems team for its outstand-ing dedication to producing the best work possible while working with determination to overcome all challenges.

“Being part of a team that works well together and is able to overcome obstacles is a big point of pride,” he says. “We’re also always learning from the mistakes of other organizations and creating a better product.”

Moving forward, Rasaiah sees 4D Systems continuing to expand and grow while staying true to its mandate of helping smaller companies achieve their own goals.

“We would like to grow our specialty robotic systems to improve quality and fill current needs,” he says. “There are some compa-nies that need robotics but aren’t sure how to go about imple-menting. We would like to help those companies.”

With a determined focus on client satisfaction while helping customers gain an edge in a competitive market, 4D Systems aids cost-effectiveness and productivity through providing and supporting world PLM solutions.

The role of robots

For those out there still wary of the role robots are playing in manufacturing and the workplace, Rasaiah stresses that while they may take some jobs, they create them, too. The robots that work in manufacturing settings to create better, more eco-logically friendly components require skilled human labor to design, engineer, build, control and maintain them.

And companies that look to 4D Systems for guidance will find everything they need, from a price that fits to a finished product that meets their needs.

“We call it early design processing,” says Rasaiah. “We think this is how it should work. We help with a company’s budget to develop different scenarios while saving money along with eliminating waste.”

Talking about what else sets 4D Systems apart from similar com-panies, Rasaiah reiterates the company’s ongoing dedication to ensuring attention is given to those companies and customers that larger organizations may tend to overlook.

“We focus on specialty robotic systems,” he says. “There are much bigger integration companies that we do not compete with, the reason being they focus on large repetitive systems. Typically, the systems that require complex vision or other complex tasks are not taken on by these companies. We work with the difficult solutions.”