Precision, Efficiency, and Innovation with 4D Systems

In the ever-evolving landscape of automotive manufacturing, precision, speed, and quality are non-negotiable. One of the most complex and delicate processes within vehicle production is sunroof assembly. From aligning and fitting glass panels to handling sensitive mechanical components, this task demands the highest levels of consistency and accuracy. That’s where robotic material handling comes in—and 4D Systems, based in Flint, Michigan, is at the forefront of delivering advanced robotic automation for sunroof assembly lines.

The Role of Robotic Material Handling in Sunroof Assembly

A vehicle sunroof is more than just a piece of glass. It involves a combination of structural, mechanical, and cosmetic elements—including:

- Glass or polycarbonate panels

- Guide rails and frame assemblies

- Drainage systems

- Motors and electronics

- Sealing and weatherproofing components

Each part must be carefully positioned and secured with high precision to ensure the sunroof is watertight, durable, and functional. This level of accuracy and consistency is exactly what robotic systems are designed to deliver.

Here’s how robotic material handling is applied to different stages of sunroof assembly:

1. Component Loading and Unloading

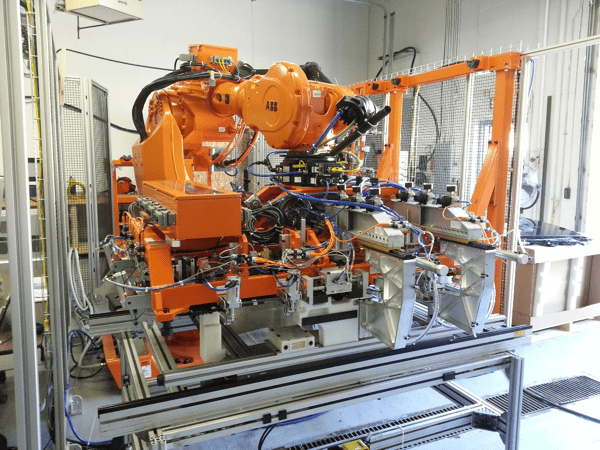

Robots equipped with vacuum grippers or specialized end effectors can automatically pick up glass panels and structural parts from pallets or trays and position them for assembly. These systems eliminate the need for manual lifting and reduce the chance of scratches, chips, or misalignment.

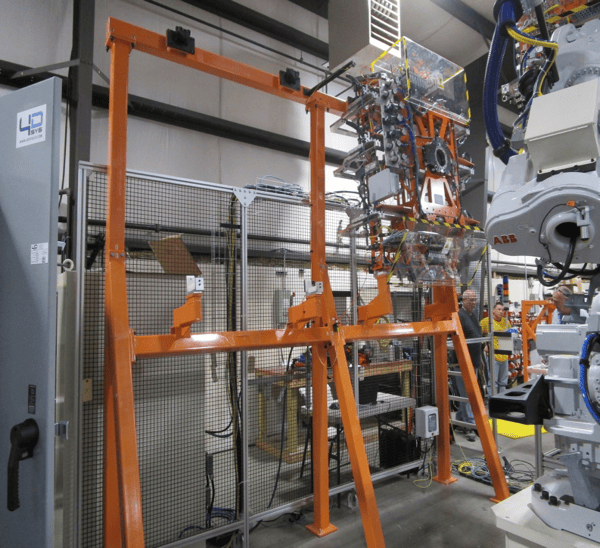

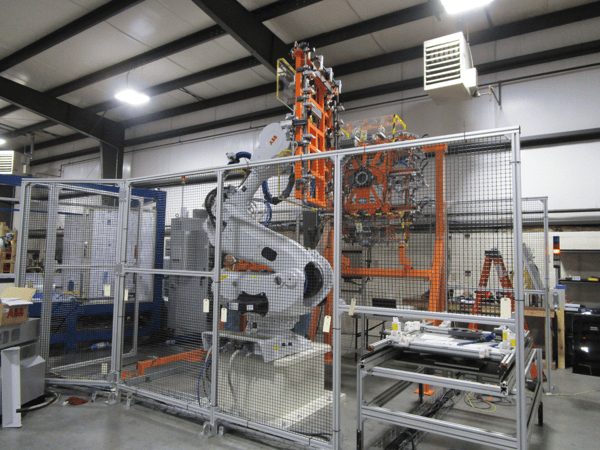

4D Systems engineers robotic cells that are tailored to specific sunroof product lines, ensuring each robot is capable of handling varying part sizes and weights while maintaining positional accuracy.

2. Precision Alignment and Placement

In sunroof assembly, accurate placement is essential for achieving proper sealing, movement, and structural integrity. Robotic arms, guided by vision systems or laser positioning sensors, can align components to within fractions of a millimeter.

For example, the glass must be precisely centered in the frame before adhesives are applied. Robots can perform this task repeatedly without deviation, eliminating human error and variation between assemblies.

3. Transfer Between Stations

A robotic handling system can move sunroof assemblies between stations—such as bonding, curing, quality inspection, and packaging—without requiring manual input. This smooth, automated flow improves cycle times and reduces work-in-progress inventory on the floor.

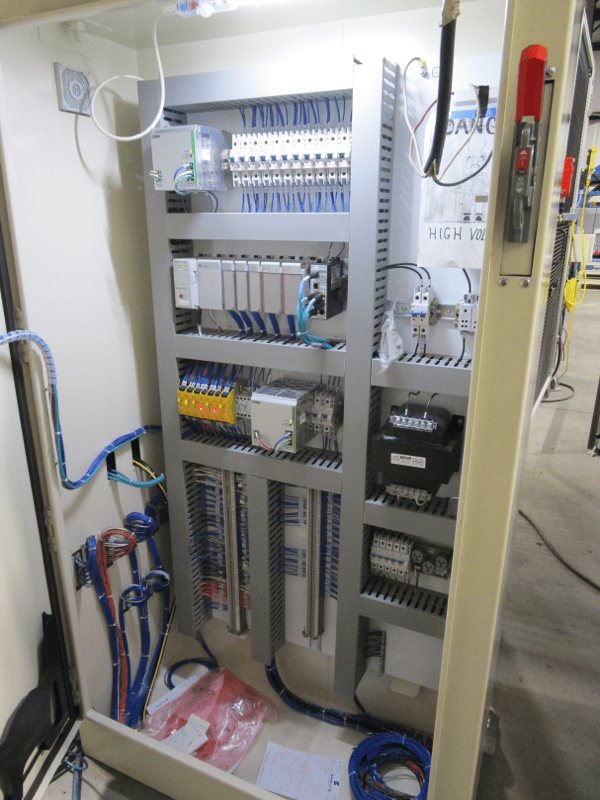

At 4D Systems, these transfer processes are engineered with safety interlocks, sensor feedback, and seamless communication between machines, creating a fully synchronized production environment.

4. Part Orientation and Fixturing

Robots are also used to orient parts at the correct angles for downstream processing, such as applying urethane adhesive or installing mounting brackets. This eliminates the need for expensive, rigid fixtures and allows for easy reconfiguration when new sunroof models are introduced.

Using multi-axis arms and programmable paths, 4D Systems enables manufacturers to respond quickly to design changes or product customization requirements.

Key Benefits of Robotic Material Handling in Sunroof Assembly

1. Improved Product Quality

By removing variation and ensuring exact repeatability, robotic systems significantly reduce the potential for defects—such as glass misalignment, frame warping, or incorrect seal application. Higher consistency leads to improved product quality and better customer satisfaction.

2. Increased Throughput

Robots don’t take breaks, call in sick, or lose focus during repetitive tasks. In high-volume automotive environments, this means continuous production with shorter cycle times and higher overall equipment effectiveness (OEE).

3. Reduced Labor and Operational Costs

Robotic material handling reduces the need for manual labor in repetitive or dangerous tasks, cutting labor costs and minimizing workplace injuries. It also reduces the need for rework or scrap due to mishandled components.

4. Enhanced Safety

Handling large glass panels or moving parts in confined spaces presents serious safety risks for human workers. Robots eliminate these risks by taking on the dangerous or strenuous jobs—especially in high-temperature, high-speed, or enclosed environments.

5. Scalable and Flexible Integration

As automotive sunroof designs evolve, so do the demands on assembly systems. 4D Systems designs robotic material handling cells with scalability in mind—meaning additional robots, vision systems, or conveyors can be added as production expands or new models are introduced.

Why Choose 4D Systems for Robotic Sunroof Assembly?

Located in Flint, Michigan, 4D Systems is a trusted robotic integrator with deep expertise in designing, engineering, and commissioning custom automation solutions for the automotive industry. Our team understands the complexities of sunroof assembly and has developed robust robotic material handling systems that meet the exacting standards of Tier 1 and OEM manufacturers.

With experience in:

- Glass panel handling

- Frame and rail assembly

- Adhesive and sealant dispensing

- Component inspection and alignment

- Machine tending and palletizing

…we are uniquely positioned to deliver turn-key solutions tailored to your plant layout, production goals, and quality requirements.

Our approach includes:

- 3D simulation and offline programming

- Custom EOAT and fixturing design

- Safety and compliance integration

- On-site commissioning and support

- Ongoing system maintenance and training

FAQ: Sunroof Assembly Using Robotic Material Handling

1. What is robotic material handling in sunroof assembly?

Robotic material handling in sunroof assembly involves using automated robots to move, position, and install components such as glass panels, frames, and seals with precision. This automation ensures consistent quality, faster cycle times, and improved safety on the production line.

2. How does automation improve the sunroof assembly process?

Automation increases production efficiency by reducing manual handling time and ensuring precise alignment during glass and frame placement. Robots minimize assembly errors, enhance repeatability, and allow manufacturers to maintain tighter quality control standards.

3. Can robotic systems handle different sunroof designs?

Yes. Modern robotic handling systems are highly flexible and can be programmed to manage various sunroof sizes, materials, and designs. With integrated vision systems, robots automatically adjust to design variations and ensure precise placement every time.

4. What components of the sunroof assembly process can be automated?

Robotic systems can automate several steps, including glass panel handling, adhesive dispensing, frame assembly, fastener placement, and final installation into vehicle roofs. They ensure consistency in every operation while minimizing human intervention.

5. What are the safety benefits of using robotic handling for sunroof assembly?

Robots eliminate the need for workers to manually handle heavy glass panels and sharp components, reducing the risk of injuries. They also minimize human exposure to adhesives and sealants, improving overall workplace safety and compliance with safety standards.

6. How does robotic material handling improve product quality?

Robotic systems offer unmatched precision and repeatability. They apply consistent force and accurate placement during assembly, reducing defects such as misalignment or uneven sealing. This ensures every sunroof meets tight OEM specifications and quality standards.

7. What is the ROI of automating the sunroof assembly process?

Companies often see a strong return on investment within a few years. Automation reduces labor costs, minimizes waste, and boosts throughput, leading to lower per-unit costs and higher production capacity—all while maintaining consistent quality output.

8. Can robotic systems integrate with existing production lines?

Yes. Robotic material handling systems can be easily integrated into existing manufacturing lines using programmable logic controllers (PLCs), conveyors, and vision-based inspection systems. They can work alongside existing automation equipment or manual stations for hybrid setups.

9. What maintenance do robotic material handling systems require?

Robotic systems require routine maintenance such as software updates, sensor calibration, and mechanical inspection. Most systems feature predictive maintenance alerts that help prevent downtime and keep production running smoothly.

10. Which industries benefit most from robotic sunroof assembly automation?

Automotive manufacturers, tier-one suppliers, and OEMs that produce high volumes of vehicles benefit most. Automation enhances consistency, reduces costs, and supports advanced manufacturing processes required for electric and luxury vehicle production.

Contact 4D Systems Today

Whether you’re launching a new sunroof production line or upgrading an existing assembly process, 4D Systems can help you unlock the full potential of robotic material handling. Our cutting-edge automation solutions improve precision, reduce cycle times, and keep your operation running efficiently—day and night.